Why Most “Recyclable” Packaging Isn’t Really Recycled

Walk into any grocery aisle, and you’ll find trays, wraps, punnets, and containers proudly stamped with the recycling symbol. It gives the impression of a circular, closed-loop system already at work. But peel back the label, and the story looks very different. Most plastic packaging—despite being technically recyclable—isn’t recovered. It’s either too complex for facilities to process or too confusing for consumers to sort correctly.

The problem isn’t one of intent, but of execution. Brands want to do the right thing. Consumers want to recycle. Legislators are pushing for accountability. But the system struggles under the weight of technical incompatibilities, inconsistent infrastructure, and unclear signals. A mono-material punnet designed for recyclability might still get tossed if its label is non-separable or if local municipalities can’t process it. Meanwhile, growing regulations in markets like California and the EU demand packaging that is actually recyclable—not just labeled that way.

For many businesses—especially mid-sized or resource-strapped ones—this isn’t just a sustainability problem. It’s a complexity problem. They’re balancing performance, cost, and now compliance, all while trying to stay focused on growth. And increasingly, they’re asking a new kind of question: not “what material is greenest,” but “who can help us make the right decision without getting lost in the weeds?”

From Material to Mindset

From Material to Mindset

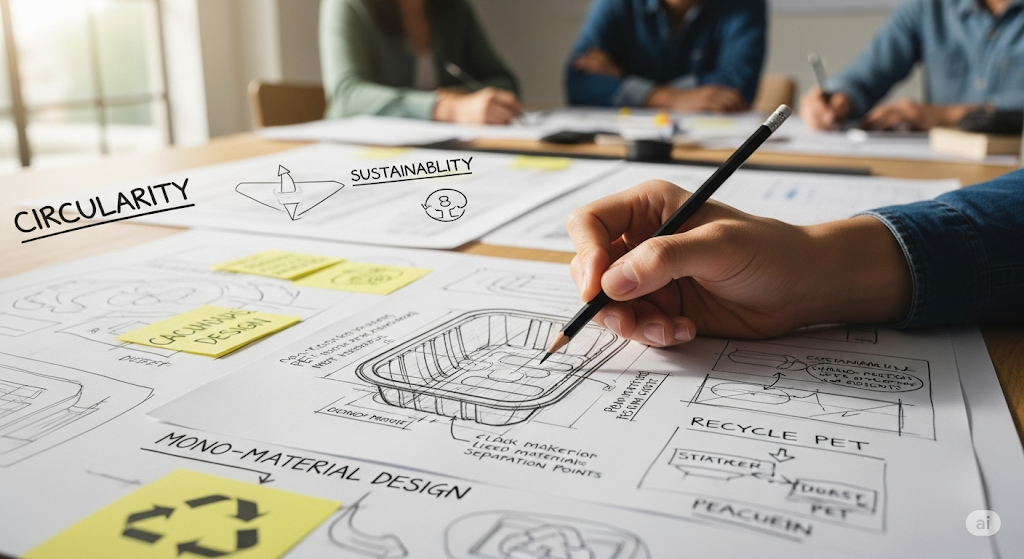

There’s a quiet revolution happening in how packaging is designed—and it’s not driven by breakthrough materials alone, but by how early and intentionally circularity is built into the design process.

Instead of defaulting to traditional formats and fixing recyclability later, forward-thinking brands are asking better questions up front: Is this design recoverable in real-world systems? Is the consumer journey clear and simple? Can we simplify without compromising performance?

Organizations like the Association of Plastic Recyclers (APR) have mapped out clear, practical frameworks to help answer these questions. Their design guides provide the kind of clarity that both engineers and marketers can act on—identifying what packaging types are considered “preferred” by recyclers and which ones introduce friction. Meanwhile, digital tools like Recycle Check allow brands to embed QR codes directly on packs—giving consumers location-specific recycling instructions at the point of use.

The real shift, though, is one of alignment. Businesses that once viewed sustainability as a compliance checkbox are now realizing it’s a driver of operational efficiency and brand trust. Clean, mono-material packaging designs reduce contamination. Clear labeling reduces customer confusion. High post-consumer recycled (PCR) content reduces reliance on virgin materials and demonstrates leadership. It’s no longer about choosing between affordability and responsibility. With the right support, you can have both.

This is especially critical for companies with lean sustainability teams or fast-moving NPD cycles. What they need isn’t just a vendor. They need a knowledgeable partner—one who can guide them through evolving regulations, material choices, and design trade-offs, while delivering standardized, scalable solutions that perform every time.

Circularity as a Partnership

At AVI Global Plast, we believe that recyclable packaging doesn’t start at the recycling bin—it starts at the drawing board.

That’s why we’re working side-by-side with businesses to design plastic packaging that’s not only technically recyclable, but practically circular. Whether it’s a blueberry punnet, a meat tray, or a deli container, we help our clients eliminate common recovery barriers through smarter design choices:

- Mono-material formats—single-material thermoformed containers that keep recycling streams clean and eliminate the need for material separation

- Smarter designs—smooth, flat protracting surfaces with non-textured label areas and no deep grooves, making labels easy to remove and preventing contamination

- Easy-to-empty structures—accessible corners and wide openings that allow complete product removal, reducing residue and ensuring cleaner recycling streams

Design is just the beginning. Our teams empower clients by integrating digital solutions like AVI Trace, a tool that tracks the lifecycle of plastic packaging, enhancing transparency and making consumer behavior a key part of the circular economy. By eliminating uncertainty for end users and streamlining decision-making for our clients’ teams, we deliver clarity at every step. Combining deep packaging expertise with comprehensive support, we ensure every project advances toward true recyclability.

We also know that for many of our partners, cost and reliability matter just as much as recyclability. That’s why we deliver with predictability: streamlined processes, on-time fulfillment, and standardized formats that reduce sourcing friction and operational headaches. From high-volume orders to customized consultations, we adapt to your needs—without adding complexity.

Whether you’re navigating your first packaging refresh or managing a portfolio of SKUs across continents, we’re here to simplify the journey—one decision, one tray, one label at a time.

Let’s Design a Circular Future – Together

Let’s Design a Circular Future – Together

Circular packaging isn’t just a trend. It’s the next chapter of packaging innovation—one that balances performance, cost, and sustainability without compromise.

At AVI Global Plast, we’re not just keeping up with change—we’re leading the charge. With technical expertise, consultative support, and dependable execution, we empower brands to deliver packaging that works for customers, operations, and the planet. Let’s build smarter, circular solutions together.

FAQ

What makes plastic packaging truly recyclable?

Packaging is truly recyclable when designed for real-world systems, using mono-material formats, separable labels with smooth surfaces, and easy-to-empty structures that ensure clean recycling streams.

How can businesses meet new recycling regulations?

Partnering with AVI Global Plast simplifies compliance with laws like California’s “Truth in Labeling” or EU 2030 goals through smart design and tools like AVI Trace.

What is AVI Trace, and how does it work?

AVI Trace is a digital tool that tracks plastic packaging’s lifecycle, providing transparency to help businesses and consumers make informed recycling decisions.

How can mid-sized businesses afford sustainable packaging?

AVI Global Plast offers affordable, standardized solutions with efficient processes, making sustainability achievable without added complexity or cost.

Why does consumer behavior matter for recycling?

Clear labeling and tools like QR codes reduce confusion, helping consumers sort correctly and preventing “wishcycling” items from landing in the wrong bins.

From Material to Mindset

From Material to Mindset

Let’s Design a Circular Future – Together

Let’s Design a Circular Future – Together