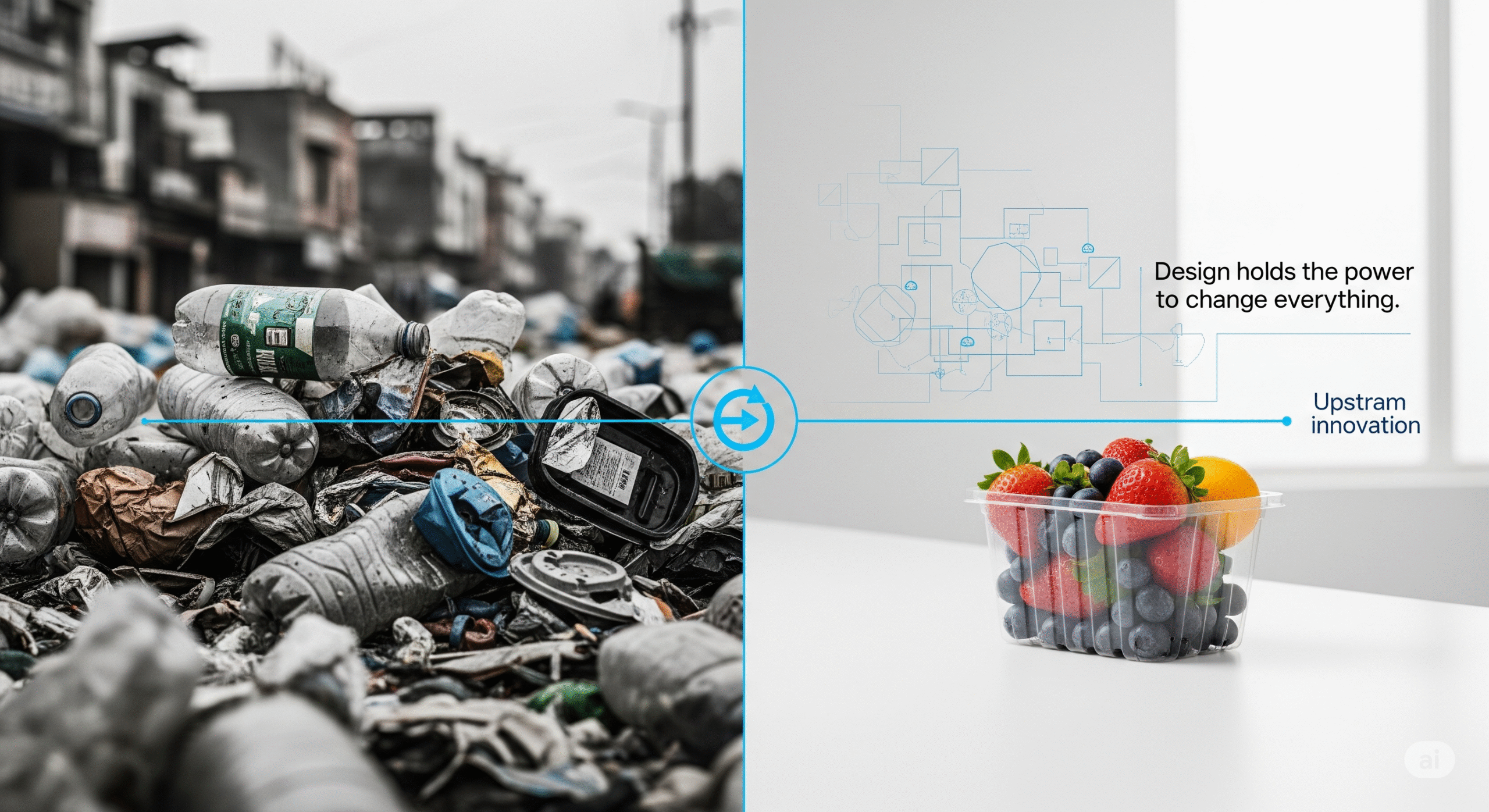

Did you know only 9% of plastic waste is recycled globally? Plastics power the modern world—from keeping food fresh to protecting medical supplies to supporting global logistics — but the way we make and dispose of them is fundamentally flawed. Our global economy still runs on a linear “take-make-dispose” model, where convenience and cost often outweigh sustainability. The result? Overflowing landfills, polluted oceans, and mounting pressure on already strained waste systems. In a country like India, millions of tons of plastic waste are generated each year, stretching infrastructure to the breaking point. Consumer preferences are also shifting: more than 70% of Indian buyers now say they prefer sustainable products, and governments are responding with strict mandates for recycling and recycled content. What used to be optional is now essential.

The problem is, traditional solutions can’t keep up. Mechanical recycling, the most common form, is riddled with challenges—plastic types are mixed, contaminated, and often incompatible with existing processes. Meanwhile, alternative materials like bio-based plastics sound promising but frequently require special conditions to break down—conditions missing in most cities and towns. Worse, they often come with high cost premiums that make them inaccessible at scale. It’s no surprise that the recycling rate has barely budged despite decades of effort. The real issue is that we’re trying to fix waste after it’s been created, rather than preventing it altogether.

That’s where upstream innovation comes in—and it changes everything.

Here’s the Kicker: Design Holds the Power to Change Everything

Upstream innovation reimagines how plastics are made, used, and reused. It’s not just a tweak—it’s a complete mindset shift. The idea is simple: design out waste before it ever becomes a problem. That starts with the materials themselves. Using recycled polymers like rPET isn’t just a sustainable move—it’s a strategic one. rPET taps into existing waste streams and can be processed using current infrastructure. It reduces dependency on virgin resin, cuts emissions, and helps manufacturers meet regulatory targets without rebuilding their systems from scratch.

But it doesn’t stop at material choice. Mono-material packaging—where only one type of plastic is used—makes recycling dramatically easier and more efficient. Add in smart packaging features like digital traceability, and you’ve got a system that not only reduces contamination but actually improves material recovery. Some closed-loop systems using these tools have seen contamination rates drop by nearly 40%. Design-for-recycling also means fewer complex shapes, fewer colors, and fewer barriers for sorting technology to overcome.

These small changes add up to big results. Manufacturers adopting upstream principles are seeing 20–40% reductions in material costs, significant drops in logistics expenses, and better alignment with recycling mandates. EPR compliance becomes easier and cheaper when packaging is built to be recycled from the beginning. AI-powered sorting technologies are pushing recovery rates above 90%, even in waste-heavy environments. For businesses operating in fast-growing sectors like food service, fresh produce in quick commerce & e-commerce, these gains translate into real resilience.

Best of all, these strategies align with market momentum. Consumers are more informed and more demanding. Regulators are raising the bar. And the companies that adapt early are the ones that will thrive.

No One Succeeds Alone: AVI’s Role in the Circular Revolution

None of this can be done in isolation. The circular economy is a system—and systems only work when everyone plays their part. In India, for example, informal waste workers collect up to 80% of all plastic waste, playing a vital yet often invisible role. Their efforts deliver recycling rates that far exceed global averages, yet they operate without the support or structure they deserve. Formalizing their work, investing in local waste infrastructure, and integrating them into mainstream supply chains isn’t just ethical—it’s essential for progress.

At AVI Global Plast, we’re not just talking about circularity—we’re building it. Upstream innovation is at the heart of everything we do. Our rPET packaging solutions are crafted from 100% post-consumer recycled content and designed for full recyclability, minimizing environmental impact while maximizing functionality. Whether it’s punnet trays for fresh produce, tamper-proof packaging for pharmacy, or custom formats for industrial goods, we engineer every solution to be lightweight, scalable, and compliant with current and upcoming regulations.

From simplified trays to intelligent closures, we reduce waste at every step.Our strategy focuses on removing unnecessary materials without compromising strength or safety. And our material circulation model ensures every product we design fits seamlessly into India’s recycling systems—whether managed by municipalities or private partners.

We also work closely with recyclers, waste collectors, and coalitions like the India Plastics Pact to advance infrastructure, share knowledge, and scale impact. From guiding brands on EPR compliance to helping retailers transition to mono-material formats, we see our role as an enabler of change. With tightening global regulations, rising resin costs, and growing demand for sustainable packaging, manufacturers can’t afford to wait. The circular economy isn’t the future—it’s already here. And it’s rewarding those who lead.

This is more than an environmental initiative. It’s a business imperative. It’s a social opportunity. It’s a design challenge. And it’s a chance to redefine value itself—not as something extracted and discarded, but as something created, reused, and regenerated.

We invite you to be part of this shift. If you’re ready to transform your packaging strategy and lead your industry toward circular success, partner with us. Visit avigloplast.com or email info@avigloplast.com to explore how we can help you turn waste into worth—and design a future that works for everyone.

Way cool, some valid points! I appreciate you making this article available, the rest of the site is also high quality. Have a fun.

I’d have to examine with you here. Which is not one thing I usually do! I take pleasure in reading a post that may make folks think. Additionally, thanks for permitting me to comment!

I discovered your blog site on google and check a few of your early posts. Continue to keep up the very good operate. I just additional up your RSS feed to my MSN News Reader. Seeking forward to reading more from you later on!…

Great line up. We will be linking to this great article on our site. Keep up the good writing.

Recently, I wanted to buy Doxycycline quickly and discovered Antibiotics Express. You can buy antibiotics without a prescription securely. For treating UTI, check this shop. Discreet packaging guaranteed. More info: z-pak no prescription. Highly recommended.

Recently, I had to find Zithromax fast and found Antibiotics Express. They let you purchase generics online legally. In case of UTI, try here. Fast shipping guaranteed. More info: http://antibioticsexpress.com/#. Get well soon.

Yay google is my king helped me to find this great web site! .

Just now, I needed Ivermectin medication and came across a great pharmacy. It offers human grade meds without a prescription. For treating scabies quickly, this is the best place: this site. Cheers

Actually, I had to buy Amoxicillin for a toothache and discovered this source. They provide antibiotics without prescription cheaply. If you are in pain, highly recommended: http://www.amoxicillinexpress.com. Hope it helps.

Salamlar, siz də etibarlı kazino axtarırsınızsa, mütləq Pin Up saytını yoxlayasınız. Ən yaxşı slotlar və sürətli ödənişlər burada mövcuddur. İndi qoşulun və bonus qazanın. Oynamaq üçün link: Pin Up online uğurlar hər kəsə!

Halo Slotter, cari situs slot yang hoki? Rekomendasi kami adalah Bonaslot. RTP Live tertinggi hari ini dan terbukti membayar. Deposit bisa pakai Dana tanpa potongan. Daftar sekarang: Bonaslot link alternatif semoga maxwin.

Bocoran slot gacor hari ini: mainkan Gate of Olympus atau Mahjong Ways di Bonaslot. Website ini gampang menang dan aman. Promo menarik menanti anda. Akses link: п»їhttps://bonaslotind.us.com/# Bonaslot login dan menangkan.

2026 yılında popüler olan casino siteleri hangileri? Detaylı liste platformumuzda mevcuttur. Bedava bahis veren siteleri ve güncel giriş linklerini paylaşıyoruz. İncelemek için türkçe casino siteleri kazanmaya başlayın.

Yeni Pin Up giriş ünvanını axtarırsınızsa, bura baxa bilərsiniz. İşlək link vasitəsilə hesabınıza girin və qazanmağa başlayın. Xoş gəldin bonusu sizi gözləyir. Keçid: https://pinupaz.jp.net/# Pinup hamıya bol şans.

Bocoran slot gacor malam ini: mainkan Gate of Olympus atau Mahjong Ways di Bonaslot. Situs ini anti rungkad dan resmi. Promo menarik menanti anda. Akses link: https://bonaslotind.us.com/# Bonaslot daftar raih kemanangan.

Hər vaxtınız xeyir, siz də keyfiyyətli kazino axtarırsınızsa, mütləq Pin Up saytını yoxlayasınız. Yüksək əmsallar və sürətli ödənişlər burada mövcuddur. Qeydiyyatdan keçin və ilk depozit bonusunu götürün. Sayta keçmək üçün link: Pin Up online uğurlar hər kəsə!

Selamlar, ödeme yapan casino siteleri arıyorsanız, bu siteye kesinlikle göz atın. Lisanslı firmaları ve fırsatları sizin için inceledik. Güvenli oyun için doğru adres: en iyi casino siteleri iyi kazançlar.

Canlı casino oynamak isteyenler için rehber niteliğinde bir site: mobil ödeme bahis Hangi site güvenilir diye düşünmeyin. Onaylı bahis siteleri listesi ile sorunsuz oynayın. Detaylar linkte.

Merhaba arkadaşlar, sağlam casino siteleri arıyorsanız, hazırladığımız listeye mutlaka göz atın. En iyi firmaları ve fırsatları sizin için listeledik. Dolandırılmamak için doğru adres: cassiteleri.us.org bol şanslar.

Canlı casino oynamak isteyenler için rehber niteliğinde bir site: güvenilir casino siteleri Nerede oynanır diye düşünmeyin. Editörlerimizin seçtiği bahis siteleri listesi ile rahatça oynayın. Tüm liste linkte.

п»їHalo Slotter, lagi nyari situs slot yang hoki? Coba main di Bonaslot. RTP Live tertinggi hari ini dan terbukti membayar. Deposit bisa pakai Pulsa tanpa potongan. Login disini: п»їsitus slot resmi semoga maxwin.

Online slot oynamak isteyenler için rehber niteliğinde bir site: https://cassiteleri.us.org/# en iyi casino siteleri Nerede oynanır diye düşünmeyin. Onaylı casino siteleri listesi ile rahatça oynayın. Tüm liste linkte.

2026 yД±lД±nda popГјler olan casino siteleri hangileri? CevabД± web sitemizde mevcuttur. Deneme bonusu veren siteleri ve yeni adres linklerini paylaЕџД±yoruz. Hemen tД±klayД±n п»їen iyi casino siteleri kazanmaya baЕџlayД±n.

Halo Slotter, lagi nyari situs slot yang mudah menang? Rekomendasi kami adalah Bonaslot. Winrate tertinggi hari ini dan pasti bayar. Isi saldo bisa pakai OVO tanpa potongan. Login disini: login sekarang salam jackpot.

Canlı casino oynamak isteyenler için rehber niteliğinde bir site: buraya tıkla Hangi site güvenilir diye düşünmeyin. Editörlerimizin seçtiği bahis siteleri listesi ile sorunsuz oynayın. Detaylar linkte.

Selam, güvenilir casino siteleri arıyorsanız, hazırladığımız listeye kesinlikle göz atın. Lisanslı firmaları ve fırsatları sizin için inceledik. Dolandırılmamak için doğru adres: buraya tıkla iyi kazançlar.

Pin-Up AZ Azərbaycanda ən populyar platformadır. Saytda çoxlu slotlar və canlı dilerlər var. Qazancı kartınıza tez köçürürlər. Proqramı də var, telefondan oynamaq çox rahatdır. Rəsmi sayt Pin Up yüklə tövsiyə edirəm.

Selamlar, sağlam casino siteleri bulmak istiyorsanız, hazırladığımız listeye kesinlikle göz atın. Lisanslı firmaları ve bonusları sizin için inceledik. Güvenli oyun için doğru adres: casino siteleri iyi kazançlar.

Bonaslot adalah bandar judi slot online terpercaya di Indonesia. Ribuan member sudah mendapatkan Maxwin sensasional disini. Proses depo WD super cepat hanya hitungan menit. Link alternatif п»їhttps://bonaslotind.us.com/# bonaslotind.us.com gas sekarang bosku.

2026 yД±lД±nda popГјler olan casino siteleri hangileri? DetaylД± liste web sitemizde mevcuttur. Bedava bahis veren siteleri ve gГјncel giriЕџ linklerini paylaЕџД±yoruz. Hemen tД±klayД±n п»їbonus veren siteler kazanmaya baЕџlayД±n.

Pin-Up AZ ölkəmizdə ən populyar platformadır. Burada çoxlu slotlar və Aviator var. Pulu kartınıza anında köçürürlər. Mobil tətbiqi də var, telefondan oynamaq çox rahatdır. Rəsmi sayt https://pinupaz.jp.net/# rəsmi sayt tövsiyə edirəm.

Pin-Up AZ Azərbaycanda ən populyar platformadır. Burada çoxlu slotlar və canlı dilerlər var. Pulu kartınıza tez köçürürlər. Mobil tətbiqi də var, telefondan oynamaq çox rahatdır. Giriş linki rəsmi sayt yoxlayın.

Online slot oynamak isteyenler için rehber niteliğinde bir site: en iyi casino siteleri Nerede oynanır diye düşünmeyin. Onaylı bahis siteleri listesi ile sorunsuz oynayın. Tüm liste linkte.

Aktual Pin Up giriş ünvanını axtaranlar, doğru yerdesiniz. Bloklanmayan link vasitəsilə hesabınıza girin və qazanmağa başlayın. Pulsuz fırlanmalar sizi gözləyir. Keçid: https://pinupaz.jp.net/# Pin Up yüklə hamıya bol şans.

Pin Up Casino ölkəmizdə ən populyar kazino saytıdır. Saytda çoxlu slotlar və Aviator var. Qazancı kartınıza tez köçürürlər. Proqramı də var, telefondan oynamaq çox rahatdır. Giriş linki https://pinupaz.jp.net/# Pin Up kazino tövsiyə edirəm.

Selamlar, güvenilir casino siteleri bulmak istiyorsanız, hazırladığımız listeye kesinlikle göz atın. En iyi firmaları ve fırsatları sizin için inceledik. Güvenli oyun için doğru adres: canlı casino siteleri iyi kazançlar.

Salam dostlar, əgər siz etibarlı kazino axtarırsınızsa, məsləhətdir ki, Pin Up saytını yoxlayasınız. Canlı oyunlar və sürətli ödənişlər burada mövcuddur. Qeydiyyatdan keçin və bonus qazanın. Oynamaq üçün link: Pin Up online uğurlar hər kəsə!

п»їHalo Slotter, lagi nyari situs slot yang gacor? Rekomendasi kami adalah Bonaslot. Winrate tertinggi hari ini dan terbukti membayar. Deposit bisa pakai Dana tanpa potongan. Login disini: п»їslot gacor hari ini salam jackpot.

2026 yılında en çok kazandıran casino siteleri hangileri? Detaylı liste platformumuzda mevcuttur. Deneme bonusu veren siteleri ve güncel giriş linklerini paylaşıyoruz. Hemen tıklayın https://cassiteleri.us.org/# kaçak bahis siteleri fırsatı kaçırmayın.

Hər vaxtınız xeyir, siz də etibarlı kazino axtarırsınızsa, məsləhətdir ki, Pin Up saytını yoxlayasınız. Yüksək əmsallar və rahat pul çıxarışı burada mövcuddur. İndi qoşulun və ilk depozit bonusunu götürün. Daxil olmaq üçün link: Pin Up giriş uğurlar hər kəsə!

Pin-Up AZ ölkəmizdə ən populyar platformadır. Burada minlərlə oyun və Aviator var. Pulu kartınıza tez köçürürlər. Proqramı də var, telefondan oynamaq çox rahatdır. Giriş linki Pin Up giriş tövsiyə edirəm.

п»їHalo Bosku, lagi nyari situs slot yang mudah menang? Coba main di Bonaslot. RTP Live tertinggi hari ini dan pasti bayar. Isi saldo bisa pakai Dana tanpa potongan. Login disini: п»їhttps://bonaslotind.us.com/# slot gacor salam jackpot.

Yeni Pin Up giriş ünvanını axtarırsınızsa, bura baxa bilərsiniz. İşlək link vasitəsilə hesabınıza girin və qazanmağa başlayın. Pulsuz fırlanmalar sizi gözləyir. Keçid: https://pinupaz.jp.net/# Pin Up AZ hamıya bol şans.

Pin-Up AZ ölkəmizdə ən populyar kazino saytıdır. Saytda çoxlu slotlar və Aviator var. Qazancı kartınıza tez köçürürlər. Proqramı də var, telefondan oynamaq çox rahatdır. Rəsmi sayt Pin Up AZ yoxlayın.

2026 yılında en çok kazandıran casino siteleri hangileri? Cevabı platformumuzda mevcuttur. Bedava bahis veren siteleri ve yeni adres linklerini paylaşıyoruz. İncelemek için casino siteleri fırsatı kaçırmayın.

2026 yılında popüler olan casino siteleri hangileri? Cevabı platformumuzda mevcuttur. Bedava bahis veren siteleri ve yeni adres linklerini paylaşıyoruz. Hemen tıklayın casino siteleri 2026 kazanmaya başlayın.

Halo Slotter, lagi nyari situs slot yang hoki? Coba main di Bonaslot. RTP Live tertinggi hari ini dan terbukti membayar. Deposit bisa pakai Dana tanpa potongan. Login disini: Bonaslot link alternatif semoga maxwin.

Selam, sağlam casino siteleri bulmak istiyorsanız, hazırladığımız listeye mutlaka göz atın. Lisanslı firmaları ve bonusları sizin için listeledik. Güvenli oyun için doğru adres: türkçe casino siteleri iyi kazançlar.

Situs Bonaslot adalah bandar judi slot online terpercaya di Indonesia. Ribuan member sudah mendapatkan Jackpot sensasional disini. Proses depo WD super cepat hanya hitungan menit. Link alternatif https://bonaslotind.us.com/# Bonaslot jangan sampai ketinggalan.

Yeni Pin Up giriş ünvanını axtaranlar, bura baxa bilərsiniz. İşlək link vasitəsilə qeydiyyat olun və oynamağa başlayın. Xoş gəldin bonusu sizi gözləyir. Keçid: https://pinupaz.jp.net/# Pin-Up Casino hamıya bol şans.

Pin-Up AZ Azərbaycanda ən populyar kazino saytıdır. Burada minlərlə oyun və canlı dilerlər var. Qazancı kartınıza tez köçürürlər. Proqramı də var, telefondan oynamaq çox rahatdır. Rəsmi sayt Pin Up AZ tövsiyə edirəm.

Bu sene en çok kazandıran casino siteleri hangileri? Cevabı platformumuzda mevcuttur. Bedava bahis veren siteleri ve güncel giriş linklerini paylaşıyoruz. İncelemek için en iyi casino siteleri fırsatı kaçırmayın.

Bonaslot adalah bandar judi slot online terpercaya di Indonesia. Ribuan member sudah merasakan Jackpot sensasional disini. Transaksi super cepat kilat. Link alternatif п»їBonaslot rtp gas sekarang bosku.

Online slot oynamak isteyenler için kılavuz niteliğinde bir site: https://cassiteleri.us.org/# bonus veren siteler Hangi site güvenilir diye düşünmeyin. Editörlerimizin seçtiği casino siteleri listesi ile rahatça oynayın. Tüm liste linkte.

Bonaslot adalah bandar judi slot online nomor 1 di Indonesia. Banyak member sudah merasakan Jackpot sensasional disini. Transaksi super cepat hanya hitungan menit. Link alternatif Bonaslot slot gas sekarang bosku.

Info slot gacor malam ini: mainkan Gate of Olympus atau Mahjong Ways di Bonaslot. Situs ini anti rungkad dan aman. Bonus new member menanti anda. Akses link: daftar situs judi slot dan menangkan.

п»їHalo Slotter, lagi nyari situs slot yang gacor? Rekomendasi kami adalah Bonaslot. Winrate tertinggi hari ini dan terbukti membayar. Isi saldo bisa pakai Pulsa tanpa potongan. Login disini: п»їslot gacor hari ini salam jackpot.

Online slot oynamak isteyenler için rehber niteliğinde bir site: https://cassiteleri.us.org/# en iyi casino siteleri Hangi site güvenilir diye düşünmeyin. Editörlerimizin seçtiği bahis siteleri listesi ile rahatça oynayın. Detaylar linkte.

Salamlar, siz də keyfiyyətli kazino axtarırsınızsa, məsləhətdir ki, Pin Up saytını yoxlayasınız. Yüksək əmsallar və rahat pul çıxarışı burada mövcuddur. Qeydiyyatdan keçin və ilk depozit bonusunu götürün. Oynamaq üçün link: bura daxil olun uğurlar hər kəsə!

Yeni Pin Up giriş ünvanını axtarırsınızsa, doğru yerdesiniz. İşlək link vasitəsilə hesabınıza girin və oynamağa başlayın. Xoş gəldin bonusu sizi gözləyir. Keçid: Pin Up giriş uğurlar.

Salam dostlar, əgər siz etibarlı kazino axtarırsınızsa, məsləhətdir ki, Pin Up saytını yoxlayasınız. Ən yaxşı slotlar və rahat pul çıxarışı burada mövcuddur. Qeydiyyatdan keçin və bonus qazanın. Sayta keçmək üçün link: https://pinupaz.jp.net/# Pin-Up Casino uğurlar hər kəsə!

Canlı casino oynamak isteyenler için rehber niteliğinde bir site: https://cassiteleri.us.org/# kaçak bahis siteleri Nerede oynanır diye düşünmeyin. Editörlerimizin seçtiği casino siteleri listesi ile sorunsuz oynayın. Detaylar linkte.

Bu sene popüler olan casino siteleri hangileri? Cevabı web sitemizde mevcuttur. Deneme bonusu veren siteleri ve güncel giriş linklerini paylaşıyoruz. Hemen tıklayın https://cassiteleri.us.org/# türkçe casino siteleri kazanmaya başlayın.

Salam Gacor, cari situs slot yang gacor? Rekomendasi kami adalah Bonaslot. RTP Live tertinggi hari ini dan pasti bayar. Deposit bisa pakai Dana tanpa potongan. Login disini: https://bonaslotind.us.com/# Bonaslot login salam jackpot.

To be honest, I recently discovered the best website for affordable pills. For those looking for ED meds safely, this site is worth checking. They offer wholesale rates worldwide. Take a look: https://indiapharm.in.net/#. Cheers.

Hey there, I just found a great online drugstore for purchasing medications online. If you need no prescription drugs, OnlinePharm is worth a look. Secure shipping plus it is very affordable. Check it out: safe online drugstore. Many thanks.

Hey guys, Lately stumbled upon an amazing website to buy generics. For those looking for medicines from India cheaply, this site is very reliable. You get fast shipping guaranteed. Check it out: https://indiapharm.in.net/#. Hope it helps.

Greetings, I just found a useful website to order generics online. If you need no prescription drugs, OnlinePharm is the best choice. They ship globally and huge selection. Visit here: https://onlinepharm.jp.net/#. Have a good one.

Greetings, I just found a great online drugstore to save on Rx. For those looking for cheap antibiotics at factory prices, IndiaPharm is the best place. You get fast shipping to USA. Check it out: https://indiapharm.in.net/#. Cheers.

Hey there, I recently discovered a reliable website to order medications securely. For those who need safe pharmacy delivery, this site is very good. They ship globally plus it is very affordable. Link here: visit website. Stay safe.

Hello everyone, I recently ran into a reliable Mexican pharmacy for affordable pills. If you want to save money and need cheap antibiotics, Pharm Mex is worth checking out. They ship to USA plus it is safe. Visit here: https://pharm.mex.com/#. Hope it helps.

Greetings, I recently discovered a useful international pharmacy where you can buy prescription drugs securely. If you are looking for safe pharmacy delivery, this site is worth a look. They ship globally plus it is very affordable. Visit here: OnlinePharm. Stay safe.

Greetings, I recently came across a great resource to buy medication. For those seeking and want meds from Mexico, this site is highly recommended. Great prices and it is safe. Take a look: Pharm Mex. Cya.

Hi all, Just now stumbled upon the best website to buy generics. If you need cheap antibiotics safely, this store is highly recommended. They offer fast shipping to USA. Visit here: order medicines from india. Good luck.

Hey everyone, I wanted to share an excellent online drugstore to order generics hassle-free. If you need safe pharmacy delivery, this store is the best choice. Fast delivery plus no script needed. Check it out: check availability. Best regards.

Hello everyone, Lately came across an awesome Mexican pharmacy to save on Rx. If you are tired of high prices and need affordable prescriptions, this store is the best option. No prescription needed plus it is safe. Link is here: check availability. Best wishes.

Hi, I recently discovered a reliable source for meds to order pills securely. If you are looking for cheap meds, this store is worth a look. Fast delivery and no script needed. Link here: https://onlinepharm.jp.net/#. Good luck with everything.

Hey everyone, I just found a great international pharmacy where you can buy prescription drugs securely. For those who need cheap meds, this store is the best choice. Great prices plus it is very affordable. Visit here: this site. Cheers.

Greetings, Lately stumbled upon the best online drugstore to save on Rx. For those looking for cheap antibiotics safely, IndiaPharm is worth checking. They offer secure delivery guaranteed. Take a look: https://indiapharm.in.net/#. Good luck.

Hey there, Just now discovered an awesome website for affordable pills. If you are tired of high prices and want meds from Mexico, this store is highly recommended. They ship to USA and very reliable. Take a look: https://pharm.mex.com/#. Thanks!

Hi, I just found a great website where you can buy medications cheaply. If you need cheap meds, OnlinePharm is worth a look. They ship globally and huge selection. See for yourself: Online Pharm Store. Good luck with everything.

Greetings, I recently stumbled upon an amazing website to buy generics. If you need ED meds safely, this site is the best place. They offer fast shipping worldwide. Check it out: click here. Best regards.

Hi, I just found a reliable online drugstore to order pills cheaply. If you are looking for antibiotics, OnlinePharm is worth a look. They ship globally and it is very affordable. See for yourself: cheap pharmacy online. Thx.

Greetings, Lately came across a great source from India to save on Rx. If you want to buy generic pills without prescription, IndiaPharm is very reliable. They offer wholesale rates to USA. Visit here: https://indiapharm.in.net/#. Best regards.

Hello, To be honest, I found an excellent source for meds for purchasing prescription drugs securely. If you need no prescription drugs, this site is very good. They ship globally plus it is very affordable. Link here: Trust Pharmacy online. Cheers.

Greetings, I recently discovered a great website for cheap meds. For those looking for ED meds safely, IndiaPharm is highly recommended. They offer secure delivery to USA. More info here: visit website. Good luck.

Hi all, Lately came across the best website to save on Rx. For those looking for ED meds without prescription, this store is worth checking. They offer lowest prices worldwide. Take a look: order medicines from india. Hope it helps.

Hello, I wanted to share a reliable international pharmacy for purchasing pills online. If you are looking for cheap meds, this store is very good. Great prices and huge selection. Link here: OnlinePharm. Warmly.

Greetings, I wanted to share a reliable international pharmacy for purchasing medications hassle-free. For those who need safe pharmacy delivery, this site is highly recommended. Great prices plus no script needed. Check it out: cheap pharmacy online. Thx.

Hey guys, Lately discovered a useful Indian pharmacy for affordable pills. If you want to buy generic pills without prescription, this site is the best place. They offer wholesale rates to USA. Check it out: https://indiapharm.in.net/#. Hope it helps.

Hi, I recently discovered a useful international pharmacy for purchasing medications cheaply. If you need safe pharmacy delivery, this store is worth a look. Secure shipping and no script needed. See for yourself: online pharmacy usa. Stay safe.

To be honest, Lately ran into a reliable Mexican pharmacy to save on Rx. For those seeking and need cheap antibiotics, this store is worth checking out. Fast shipping and it is safe. Visit here: https://pharm.mex.com/#. Best of luck.

Hi guys, I recently ran into a great website for affordable pills. For those seeking and want generic drugs, this site is highly recommended. No prescription needed plus very reliable. Take a look: read more. Have a nice day.

Hello, To be honest, I found a great source for meds to order medications hassle-free. If you are looking for cheap meds, this store is the best choice. They ship globally plus it is very affordable. See for yourself: buy meds online. Thank you.

Hey there, To be honest, I found a reliable international pharmacy for purchasing prescription drugs securely. If you need antibiotics, OnlinePharm is the best choice. They ship globally and huge selection. Link here: online pharmacy no prescription. Best of luck.

Hello, I just stumbled upon an amazing source from India for affordable pills. If you need generic pills at factory prices, this store is worth checking. They offer secure delivery worldwide. Take a look: visit website. Best regards.

Greetings, I wanted to share a useful website where you can buy prescription drugs cheaply. If you need no prescription drugs, this site is the best choice. They ship globally plus it is very affordable. Link here: https://onlinepharm.jp.net/#. Stay healthy.

To be honest, I just came across an awesome resource for affordable pills. For those seeking and need affordable prescriptions, this store is the best option. No prescription needed plus it is safe. Take a look: cheap antibiotics mexico. Warmly.

Greetings, Lately discovered a great source from India to buy generics. If you want to buy ED meds cheaply, this store is highly recommended. They offer secure delivery guaranteed. More info here: indiapharm.in.net. Hope it helps.

Hey everyone, To be honest, I found a reliable international pharmacy to order prescription drugs cheaply. For those who need safe pharmacy delivery, this store is very good. Great prices plus no script needed. Link here: https://onlinepharm.jp.net/#. Best wishes.

Hey there, To be honest, I found an excellent source for meds where you can buy pills online. If you are looking for antibiotics, this store is highly recommended. Fast delivery plus it is very affordable. Link here: safe online drugstore. I hope you find what you need.

Hello everyone, Lately ran into an awesome Mexican pharmacy to buy medication. If you are tired of high prices and want generic drugs, Pharm Mex is the best option. Great prices plus secure. Take a look: https://pharm.mex.com/#. Have a nice day.

Hey there, I wanted to share a great international pharmacy where you can buy generics hassle-free. For those who need safe pharmacy delivery, this site is worth a look. They ship globally plus no script needed. Visit here: Online Pharm Store. Be well.

To be honest, Lately came across a trusted online source for affordable pills. If you want to save money and want cheap antibiotics, Pharm Mex is a game changer. No prescription needed and secure. Visit here: this site. Peace.

Hey there, I just found a great online drugstore for purchasing generics hassle-free. For those who need safe pharmacy delivery, OnlinePharm is the best choice. Great prices and it is very affordable. See for yourself: safe online drugstore. Thx.

To be honest, Just now found a useful online drugstore to save on Rx. If you want to buy cheap antibiotics at factory prices, this store is very reliable. It has wholesale rates guaranteed. Visit here: IndiaPharm. Hope it helps.

Hi guys, I just ran into a reliable website to save on Rx. If you are tired of high prices and want meds from Mexico, this site is highly recommended. No prescription needed plus very reliable. Take a look: https://pharm.mex.com/#. Thanks!

Hi guys, I just came across a reliable online source for cheap meds. If you are tired of high prices and want meds from Mexico, this store is a game changer. Great prices plus secure. Visit here: visit website. Best wishes.

Greetings, I recently ran into a trusted resource to buy medication. If you want to save money and need affordable prescriptions, this store is worth checking out. They ship to USA plus it is safe. Take a look: https://pharm.mex.com/#. Hope it helps.

To be honest, I recently came across a great resource for affordable pills. For those seeking and need cheap antibiotics, this store is highly recommended. They ship to USA and it is safe. Take a look: visit website. Many thanks.

Greetings, I just ran into a trusted Mexican pharmacy for affordable pills. For those seeking and need meds from Mexico, this store is highly recommended. Great prices and it is safe. Check it out: buy meds from mexico. Thanks!

Hello, Lately stumbled upon a great online drugstore to buy generics. For those looking for ED meds at factory prices, this site is highly recommended. They offer lowest prices to USA. More info here: https://indiapharm.in.net/#. Hope it helps.

Greetings, I just discovered a reliable resource for affordable pills. If you want to save money and need cheap antibiotics, Pharm Mex is worth checking out. Great prices and secure. Link is here: https://pharm.mex.com/#. Regards.

Hello, Lately discovered a great Indian pharmacy for affordable pills. For those looking for ED meds safely, IndiaPharm is highly recommended. You get fast shipping worldwide. Check it out: indian pharmacy. Good luck.

Greetings, I just discovered a great Mexican pharmacy for cheap meds. If you want to save money and want meds from Mexico, Pharm Mex is highly recommended. They ship to USA plus very reliable. Visit here: safe mexican pharmacy. Kind regards.

Hey there, I recently found a great online source to save on Rx. If you are tired of high prices and want meds from Mexico, Pharm Mex is worth checking out. No prescription needed and it is safe. Check it out: mexican pharmacy. Cheers.

Greetings, Just now ran into a trusted website for cheap meds. If you want to save money and need cheap antibiotics, this store is the best option. Fast shipping plus it is safe. Visit here: https://pharm.mex.com/#. Stay safe.

Greetings, Just now found a great Mexican pharmacy for cheap meds. For those seeking and need cheap antibiotics, Pharm Mex is a game changer. Great prices plus very reliable. Visit here: Pharm Mex Store. Have a nice day.

To be honest, Just now came across an awesome Mexican pharmacy to buy medication. If you are tired of high prices and want affordable prescriptions, this store is worth checking out. Fast shipping plus it is safe. Visit here: Pharm Mex Store. Stay healthy.

Greetings, Just now found the best online drugstore to buy generics. If you need cheap antibiotics without prescription, this store is worth checking. They offer fast shipping guaranteed. More info here: check availability. Hope it helps.

Matbet TV giris linki laz?msa iste burada. H?zl? icin: Matbet Mobil Yuksek oranlar bu sitede. Arkadaslar, Matbet bahis yeni adresi belli oldu.

Herkese selam, Casibom sitesi kullan?c?lar? icin k?sa bir bilgilendirme paylas?yorum. Bildiginiz gibi bahis platformu domain adresini BTK engeli yuzunden tekrar guncelledi. Giris sorunu yas?yorsan?z cozum burada. Resmi siteye erisim baglant?s? art?k paylas?yorum https://casibom.mex.com/# Bu link uzerinden direkt siteye girebilirsiniz. Ayr?ca yeni uyelere sunulan yat?r?m bonusu kampanyalar?n? da kac?rmay?n. En iyi casino deneyimi surdurmek icin Casibom tercih edebilirsiniz. Tum forum uyelerine bol sans dilerim.

Herkese merhaba, bu site oyuncuları için kısa bir duyuru paylaşıyorum. Malum Vaycasino giriş linkini yine güncelledi. Giriş sorunu yaşıyorsanız panik yapmayın. Yeni Vaycasino giriş linki artık aşağıdadır: Buraya Tıkla Bu link ile direkt siteye girebilirsiniz. Güvenilir casino deneyimi sürdürmek için Vay Casino tercih edebilirsiniz. Tüm forum üyelerine bol kazançlar temenni ederim.

Arkadaşlar, Grandpashabet Casino son linki belli oldu. Adresi bulamayanlar buradan devam edebilir Grandpasha Giriş

Matbet giris adresi laz?msa iste burada. Sorunsuz icin: https://matbet.jp.net/# Canl? maclar bu sitede. Gencler, Matbet bahis son linki ac?kland?.

Arkadaşlar selam, Casibom sitesi oyuncuları adına kısa bir bilgilendirme paylaşıyorum. Bildiğiniz gibi bahis platformu domain adresini BTK engeli yüzünden sürekli taşıdı. Erişim sorunu çekenler için link aşağıda. Yeni Casibom güncel giriş bağlantısı şu an burada Casibom Apk Paylaştığım bağlantı üzerinden direkt siteye girebilirsiniz. Ayrıca kayıt olanlara sunulan freespin fırsatlarını da kaçırmayın. Güvenilir bahis keyfi için Casibom tercih edebilirsiniz. Herkese bol şans dilerim.

Arkadaslar, Grandpashabet yeni adresi ac?kland?. Adresi bulamayanlar buradan giris yapabilir https://grandpashabet.in.net/#

Dostlar selam, Casibom oyuncuları adına kısa bir duyuru paylaşıyorum. Herkesin bildiği üzere Casibom adresini erişim kısıtlaması nedeniyle sürekli değiştirdi. Giriş sorunu varsa çözüm burada. Güncel Casibom giriş bağlantısı şu an paylaşıyorum https://casibom.mex.com/# Paylaştığım bağlantı ile direkt siteye erişebilirsiniz. Ayrıca yeni üyelere sunulan freespin fırsatlarını mutlaka inceleyin. Güvenilir slot keyfi sürdürmek için Casibom tercih edebilirsiniz. Herkese bol şans dilerim.

Grandpasha guncel adresi laz?msa dogru yerdesiniz. Sorunsuz erisim icin t?kla https://grandpashabet.in.net/# Yuksek oranlar bu sitede.

Arkadaşlar, Grandpashabet Casino yeni adresi belli oldu. Giremeyenler buradan giriş yapabilir Buraya Tıkla

Arkadaslar, Grandpashabet son linki ac?kland?. Adresi bulamayanlar su linkten devam edebilir Grandpashabet Guncel

Arkadaslar, Grandpashabet Casino son linki ac?kland?. Adresi bulamayanlar su linkten giris yapabilir Grandpasha Giris

Herkese selam, Vaycasino oyuncuları için kısa bir bilgilendirme yapmak istiyorum. Malum Vaycasino giriş linkini tekrar değiştirdi. Giriş sorunu yaşıyorsanız panik yapmayın. Yeni Vay Casino giriş adresi şu an aşağıdadır: Vay Casino Güncel Adres Paylaştığım bağlantı üzerinden direkt siteye erişebilirsiniz. Güvenilir casino keyfi için Vay Casino doğru adres. Herkese bol kazançlar temenni ederim.

Herkese merhaba, bu populer site oyuncular? icin onemli bir bilgilendirme paylas?yorum. Bildiginiz gibi bahis platformu adresini erisim k?s?tlamas? nedeniyle tekrar degistirdi. Siteye ulas?m problemi varsa cozum burada. Son Casibom giris adresi su an paylas?yorum Siteye Git Paylast?g?m baglant? ile dogrudan siteye girebilirsiniz. Ek olarak yeni uyelere sunulan hosgeldin bonusu kampanyalar?n? da inceleyin. Guvenilir casino deneyimi surdurmek icin Casibom tercih edebilirsiniz. Tum forum uyelerine bol kazanclar dilerim.

Dostlar selam, bu popüler site oyuncuları adına önemli bir paylaşım yapmak istiyorum. Bildiğiniz gibi bahis platformu giriş linkini erişim kısıtlaması nedeniyle tekrar değiştirdi. Giriş hatası varsa link aşağıda. Çalışan siteye erişim bağlantısı artık paylaşıyorum Resmi Site Bu link üzerinden direkt hesabınıza bağlanabilirsiniz. Ayrıca yeni üyelere verilen freespin fırsatlarını mutlaka kaçırmayın. Lisanslı slot keyfi sürdürmek için Casibom doğru adres. Tüm forum üyelerine bol şans dilerim.

Arkadaslar, Grandpashabet Casino son linki belli oldu. Giremeyenler su linkten giris yapabilir Resmi Site

Grandpasha guncel adresi ar?yorsan?z iste burada. Sorunsuz erisim icin https://grandpashabet.in.net/# Deneme bonusu bu sitede.

Gençler, Grandpashabet Casino yeni adresi belli oldu. Adresi bulamayanlar buradan giriş yapabilir https://grandpashabet.in.net/#

Grandpashabet giris linki laz?msa iste burada. Sorunsuz erisim icin Grandpashabet Guvenilir mi Deneme bonusu burada.

Dostlar selam, Casibom sitesi kullanıcıları için önemli bir bilgilendirme paylaşıyorum. Bildiğiniz gibi Casibom domain adresini erişim kısıtlaması nedeniyle sürekli taşıdı. Giriş hatası varsa çözüm burada. Çalışan Casibom güncel giriş adresi şu an paylaşıyorum Casibom Yeni Adres Bu link ile doğrudan hesabınıza bağlanabilirsiniz. Ek olarak kayıt olanlara sunulan hoşgeldin bonusu kampanyalarını da inceleyin. Lisanslı slot deneyimi için Casibom doğru adres. Herkese bol kazançlar dilerim.

Arkadaslar selam, Casibom sitesi uyeleri ad?na k?sa bir paylas?m paylas?yorum. Herkesin bildigi uzere site giris linkini erisim k?s?tlamas? nedeniyle tekrar guncelledi. Giris sorunu cekenler icin dogru yerdesiniz. Resmi Casibom guncel giris linki art?k burada Hemen Oyna Bu link ile direkt siteye girebilirsiniz. Ayr?ca kay?t olanlara verilen freespin kampanyalar?n? da inceleyin. Guvenilir slot keyfi icin Casibom dogru adres. Herkese bol kazanclar dilerim.

Herkese merhaba, Vay Casino kullan?c?lar? icin k?sa bir bilgilendirme paylas?yorum. Malum site adresini tekrar degistirdi. Giris hatas? varsa panik yapmay?n. Guncel siteye erisim linki art?k asag?dad?r: Vaycasino Kay?t Bu link uzerinden dogrudan siteye girebilirsiniz. Lisansl? bahis keyfi surdurmek icin Vaycasino dogru adres. Tum forum uyelerine bol kazanclar temenni ederim.

Arkadaşlar, Grandpashabet Casino yeni adresi belli oldu. Adresi bulamayanlar buradan giriş yapabilir Grandpashabet

Herkese selam, bu site oyuncular? icin k?sa bir duyuru paylas?yorum. Malum Vaycasino adresini yine degistirdi. Giris sorunu varsa panik yapmay?n. Yeni Vay Casino giris adresi art?k asag?dad?r: https://vaycasino.us.com/# Paylast?g?m baglant? uzerinden dogrudan hesab?n?za girebilirsiniz. Guvenilir casino keyfi icin Vay Casino dogru adres. Herkese bol kazanclar temenni ederim.

Matbet giriş adresi arıyorsanız doğru yerdesiniz. Sorunsuz için tıkla: Matbet TV Giriş Yüksek oranlar burada. Arkadaşlar, Matbet yeni adresi belli oldu.

Grandpasha guncel adresi ar?yorsan?z dogru yerdesiniz. Sorunsuz erisim icin Grandpasha Giris Deneme bonusu burada.

Matbet guncel linki ar?yorsan?z dogru yerdesiniz. H?zl? icin: https://matbet.jp.net/# Canl? maclar bu sitede. Gencler, Matbet bahis yeni adresi ac?kland?.

Arkadaslar selam, bu site oyuncular? icin onemli bir duyuru yapmak istiyorum. Malum site adresini yine degistirdi. Giris sorunu yas?yorsan?z endise etmeyin. Guncel Vay Casino giris linki su an burada: https://vaycasino.us.com/# Paylast?g?m baglant? ile vpn kullanmadan siteye erisebilirsiniz. Guvenilir casino deneyimi surdurmek icin Vaycasino dogru adres. Tum forum uyelerine bol kazanclar temenni ederim.

Chao c? nha, n?u anh em dang ki?m nha cai uy tin d? cay cu?c Casino d?ng b? qua ch? nay. Dang co khuy?n mai: https://pacebhadrak.org.in/#. Chi?n th?ng nhe.

Hi cac bac, ai dang tim trang choi xanh chin d? gi?i tri Casino d?ng b? qua ch? nay. Khong lo l?a d?o: sunwin. Hup l?c d?y nha.

Hello m?i ngu?i, ai dang tim nha cai uy tin d? g? g?c Tai X?u thi xem th? ch? nay. Dang co khuy?n mai: sun win. Hup l?c d?y nha.

Chao anh em, ngu?i anh em nao c?n ch? n?p rut nhanh d? g? g?c N? Hu thi xem th? trang nay nhe. T?c d? ban th?: https://gramodayalawcollege.org.in/#. Hup l?c d?y nha.

Chào cả nhà, bác nào muốn tìm sân chơi đẳng cấp để chơi Tài Xỉu thì vào ngay địa chỉ này. Không lo lừa đảo: bj88. Về bờ thành công.

Chao c? nha, ai dang tim c?ng game khong b? ch?n d? choi Casino thi xem th? ch? nay. N?p rut 1-1: BJ88. Chi?n th?ng nhe.

Hello mọi người, người anh em nào cần cổng game không bị chặn để gỡ gạc Game bài thì vào ngay địa chỉ này. Tốc độ bàn thờ: https://pacebhadrak.org.in/#. Chúc anh em may mắn.

Chào anh em, nếu anh em đang kiếm chỗ nạp rút nhanh để cày cuốc Đá Gà thì tham khảo con hàng này. Tốc độ bàn thờ: https://pacebhadrak.org.in/#. Húp lộc đầy nhà.

stromectol 6 mg dosage: Iver Protocols Guide – Iver Protocols Guide

ivermectin buy Iver Protocols Guide ivermectin lotion

ivermectin where to buy: ivermectin price uk – Iver Protocols Guide

Amitriptyline Elavil Elavil

Elavil: Amitriptyline – Amitriptyline

Elavil: AmiTrip Relief Store – AmiTrip Relief Store

order cheap clomid without prescription: where can i buy clomid for sale – buy generic clomid prices

https://fertilitypctguide.us.com/# fertility pct guide

get generic propecia without insurance Follicle Insight Follicle Insight

https://fertilitypctguide.us.com/# fertility pct guide

Elavil: AmiTrip Relief Store – AmiTrip

can you buy cheap clomid without dr prescription: fertility pct guide – cost clomid no prescription

https://fertilitypctguide.us.com/# how can i get cheap clomid price

https://fertilitypctguide.us.com/# fertility pct guide

how to get generic clomid for sale: fertility pct guide – fertility pct guide

rx propecia: Follicle Insight – Follicle Insight

https://amitrip.us.com/# AmiTrip Relief Store

buy propecia tablets propecia cost Follicle Insight

buying cheap propecia price: generic propecia without dr prescription – order propecia without dr prescription

can i buy generic clomid no prescription: can you get clomid without prescription – fertility pct guide

https://amitrip.us.com/# Amitriptyline

https://fertilitypctguide.us.com/# get generic clomid without rx

Iver Protocols Guide: Iver Protocols Guide – Iver Protocols Guide

buy clomid without rx: order clomid tablets – fertility pct guide

https://iver.us.com/# Iver Protocols Guide

https://fertilitypctguide.us.com/# can i order cheap clomid without rx

buy generic propecia: buy generic propecia without a prescription – Follicle Insight

can i get cheap clomid prices: fertility pct guide – fertility pct guide

https://amitrip.us.com/# AmiTrip

Follicle Insight: propecia tablets – cost generic propecia prices

can you get generic clomid for sale: fertility pct guide – where can i buy cheap clomid without a prescription

https://follicle.us.com/# Follicle Insight

https://amitrip.us.com/# AmiTrip Relief Store

buying cheap clomid without insurance: clomid without dr prescription – can i order cheap clomid for sale

fertility pct guide: fertility pct guide – can you buy clomid prices

Generic Elavil AmiTrip Relief Store buy Elavil

https://amitrip.us.com/# AmiTrip Relief Store

https://follicle.us.com/# Follicle Insight

Follicle Insight: Follicle Insight – Follicle Insight

AmiTrip Relief Store: Amitriptyline – Elavil

https://amitrip.us.com/# buy Elavil

AmiTrip Relief Store: Generic Elavil – AmiTrip Relief Store

get propecia no prescription: cost cheap propecia without insurance – cost cheap propecia tablets

https://fertilitypctguide.us.com/# buying generic clomid without insurance

https://iver.us.com/# stromectol price

where to buy stromectol online ivermectin cream cost ivermectin cream cost

Amitriptyline: Elavil – Amitriptyline

cost of clomid without a prescription: how can i get clomid for sale – fertility pct guide

Hey everyone, if you need a reliable source for meds to order health products securely. Take a look at this site: flonase. Selling a wide range of meds and huge discounts. Hope this helps.

Greetings, if you are looking for detailed information regarding health treatments, check out this health wiki. It covers safety protocols in detail. Reference: https://magmaxhealth.com/Olanzapine. Hope it helps.

Greetings, I recently found a medical guide on common medicines, check out this drug database. It covers safety protocols in detail. See details: https://magmaxhealth.com/Naltrexone. Thanks.

regarding the proper usage instructions, please review the official information page at: https://magmaxhealth.com/protonix.html to ensure clinical details.

Hi guys, if you need a reliable source for meds to buy medicines hassle-free. Take a look at this site: lipitor. They offer high quality drugs at the best prices. Good luck.

To start saving, I recommend this top-rated pharmacy reputable indian online pharmacy for the best prices. Get your meds today and save big.

Hi, if you are looking for detailed information regarding various medications, check out this online directory. You can read about how to take meds very well. Reference: https://magmaxhealth.com. Hope this is useful.

To start saving, I recommend this reliable site cheapest prescription pharmacy for fast USA shipping. Take control of your health and save big.

Hi all, for those searching for side effects info regarding common medicines, take a look at this medical reference. You can read about how to take meds clearly. Link: https://magmaxhealth.com/Lamictal. Very informative.

To understand the proper usage instructions, you can consult the detailed guide on: https://magmaxhealth.com/meclizine.html to ensure safe treatment.

Hey everyone, I recently found side effects info about health treatments, check out this drug database. It explains drug interactions in detail. See details: https://magmaxhealth.com/Meclizine. Good info.

Hey everyone, if you need an affordable online pharmacy to buy prescription drugs cheaply. I found this site: prilosec. Selling high quality drugs with fast shipping. Cheers.

For a complete overview of medical specifications, you can consult this resource: https://magmaxhealth.com/celebrex.html for clinical details.

Hello, I recently found side effects info about prescription drugs, I found this drug database. It explains usage and risks clearly. Link: https://magmaxhealth.com/Rosuvastatin. Good info.

Hi all, I recently found detailed information about health treatments, check out this drug database. It covers safety protocols clearly. Link: https://magmaxhealth.com/Celebrex. Hope it helps.

In terms of dosage guidelines, you can consult the official information page at: https://magmaxhealth.com/lamictal.html for risk management.

Hey everyone, for those searching for a useful article regarding common medicines, I recommend this medical reference. You can read about drug interactions clearly. Read more here: https://magmaxhealth.com/Celebrex. Thanks.

Hey everyone, if you are looking for a reliable drugstore to buy health products online. Check out this pharmacy: rosuvastatin. Stocking a wide range of meds with fast shipping. Good luck.

Hey everyone, I recently found a medical guide about prescription drugs, I recommend this online directory. You can read about how to take meds clearly. Source: https://magmaxhealth.com/Prilosec. Hope this is useful.

buy prilosec: Gastro Health Monitor – omeprazole generic

Gastro Health Monitor Gastro Health Monitor Gastro Health Monitor

https://nauseacareus.shop/# Nausea Care US

zanaflex: Spasm Relief Protocols – tizanidine muscle relaxer

tizanidine hydrochloride: Spasm Relief Protocols – robaxin generic

zofran over the counter: buy zofran online – buy zofran online

https://spasmreliefprotocols.shop/# muscle relaxer medication

buy prilosec: Gastro Health Monitor – omeprazole brand name

omeprazole: prilosec dosage – Gastro Health Monitor

prilosec dosage: buy prilosec online – prilosec omeprazole

http://gastrohealthmonitor.com/# prilosec omeprazole

http://spasmreliefprotocols.com/# tizanidine generic

Nausea Care US: ondansetron otc – ondansetron otc

antispasmodic medication: robaxin medication – muscle relaxer tizanidine

п»їondansetron otc generic zofran Nausea Care US

ondansetron: zofran side effects – Nausea Care US

muscle relaxant drugs: best muscle relaxer – buy tizanidine without prescription

https://nauseacareus.com/# Nausea Care US

ondestranon zofran: Nausea Care US – Nausea Care US

Gastro Health Monitor: prilosec otc – buy prilosec

omeprazole brand name: prilosec omeprazole – prilosec medication

Nausea Care US: ondansetron – Nausea Care US

zofran generic: generic for zofran – Nausea Care US

https://spasmreliefprotocols.com/# methocarbamol dosing

otc muscle relaxer: tizanidine zanaflex – muscle relaxers for back pain

generic zofran: zofran side effects – Nausea Care US

Gastro Health Monitor: Gastro Health Monitor – prilosec generic

tizanidine medication: muscle relaxers for back pain – buy tizanidine without prescription

http://spasmreliefprotocols.com/# buy methocarbamol

ondansetron: zofran side effects – Nausea Care US

omeprazole: Gastro Health Monitor – Gastro Health Monitor

omeprazole: omeprazole prilosec – omeprazole brand name

ondansetron zofran: Nausea Care US – zofran otc

http://spasmreliefprotocols.com/# tizanidine medication

muscle relaxer tizanidine: Spasm Relief Protocols – methocarbamol dosing

Gastro Health Monitor: prilosec otc – omeprazole generic

tizanidine medication: buy methocarbamol – zanaflex medication

http://nauseacareus.com/# ondansetron medication

Gastro Health Monitor: prilosec generic – Gastro Health Monitor

tizanidine hydrochloride: Spasm Relief Protocols – antispasmodic medication

https://spasmreliefprotocols.com/# methocarbamol dosing

generic prilosec: Gastro Health Monitor – Gastro Health Monitor

https://gastrohealthmonitor.com/# omeprazole brand name

methocarbamol dosing: Spasm Relief Protocols – tizanidine muscle relaxer

https://nauseacareus.shop/# ondestranon zofran

https://spasmreliefprotocols.shop/# muscle relaxers over the counter

buy methocarbamol: Spasm Relief Protocols – tizanidine zanaflex

http://spasmreliefprotocols.com/# antispasmodic medication

Gastro Health Monitor: Gastro Health Monitor – omeprazole generic

https://spasmreliefprotocols.shop/# muscle relaxers over the counter

http://gastrohealthmonitor.com/# omeprazole otc

buy prilosec online: omeprazole generic – Gastro Health Monitor

muscle relaxant drugs: Spasm Relief Protocols – muscle relaxer medication

https://indogenericexport.shop/# tizanidine zanaflex

www canadianonlinepharmacy: usa pharmacy – australia online pharmacy free shipping

https://usmedsoutlet.com/# US Meds Outlet

https://indogenericexport.com/# tizanidine generic

top 10 pharmacies in india: indianpharmacy com – online shopping pharmacy india

https://usmedsoutlet.com/# online pharmacy canada

https://bajameddirect.com/# mexican medicine

indian pharmacy paypal: buy medicines online in india – indianpharmacy com

https://bajameddirect.com/# BajaMed Direct

https://indogenericexport.com/# pharmacy website india

https://indogenericexport.com/# muscle relaxers over the counter

online pharmacy group: US Meds Outlet – US Meds Outlet

https://indogenericexport.com/# methocarbamol dosing

US Meds Outlet: US Meds Outlet – pharmacy orlando

mexico online pharmacy: BajaMed Direct – mexican mail order pharmacy

https://bajameddirect.shop/# BajaMed Direct

prescription drugs online: the pharmacy – trustworthy online pharmacy

http://indogenericexport.com/# robaxin

US Meds Outlet: US Meds Outlet – US Meds Outlet

world pharmacy india: Online medicine order – mail order pharmacy india

http://indogenericexport.com/# tizanidine zanaflex

reputable indian online pharmacy: Indo-Generic Export – indian pharmacy paypal

https://usmedsoutlet.shop/# tops pharmacy

BajaMed Direct: BajaMed Direct – BajaMed Direct

online pharmacy india: Indo-Generic Export – buy medicines online in india

https://bajameddirect.shop/# order medicine from mexico

mexican pharmacies that ship to the united states: mexico pharmacy list – BajaMed Direct

BajaMed Direct: mexican online pharmacy – BajaMed Direct

indian pharmacy paypal: Indo-Generic Export – indian pharmacy

US Meds Outlet: US Meds Outlet – US Meds Outlet

phentermine in mexico pharmacy: purple pharmacy – farmacia mexicana online

mexican pharmacy ship to usa: mexico prescriptions – BajaMed Direct

http://bajameddirect.com/# BajaMed Direct

US Meds Outlet: canadian pharmacy – US Meds Outlet

https://indogenericexport.com/# best india pharmacy

US Meds Outlet: US Meds Outlet – 24 hour pharmacy

buy online pharmacy uk: canadian pharmacy no prescription needed – thecanadianpharmacy

https://bajameddirect.com/# medicine mexico

pharmacy website india: Indo-Generic Export – п»їlegitimate online pharmacies india

http://bajameddirect.com/# BajaMed Direct

best australian online pharmacy: indian pharmacies safe – US Meds Outlet

rx pharmacy coupons: online pharmacy denmark – US Meds Outlet

https://usmedsoutlet.com/# US Meds Outlet

best online canadian pharmacy: US Meds Outlet – US Meds Outlet

online pharmacy without insurance: canadian pharmacy world coupon – best rated canadian pharmacy

http://usmedsoutlet.com/# US Meds Outlet

best online pharmacy: reputable online pharmacy uk – US Meds Outlet

https://bajameddirect.shop/# mexico pharmacy price list

US Meds Outlet: legit pharmacy websites – canada drugs

india pharmacy mail order: india online pharmacy – online pharmacy india

https://indogenericexport.com/# Online medicine home delivery

pharmacy mall: US Meds Outlet – US Meds Outlet

https://sertralineusa.com/# zoloft cheap

Smart GenRx USA: Smart GenRx USA – best no prescription pharmacy

https://ivertherapeutics.com/# stromectol price us

Smart GenRx USA: Smart GenRx USA – Smart GenRx USA

http://smartgenrxusa.com/# medstore online pharmacy

ivermectin buy online: Iver Therapeutics – stromectol cvs

https://smartgenrxusa.com/# Smart GenRx USA

buying prescription drugs from canada: list of online pharmacies – Smart GenRx USA

https://smartgenrxusa.com/# Smart GenRx USA

Iver Therapeutics: stromectol oral – oral ivermectin cost

http://smartgenrxusa.com/# Smart GenRx USA

https://ivertherapeutics.com/# Iver Therapeutics

Smart GenRx USA: mexican pharmacy – non prescription medicine pharmacy

https://ivertherapeutics.shop/# Iver Therapeutics

neurontin 300: Neuro Relief USA – Neuro Relief USA

http://sertralineusa.com/# generic for zoloft

online pharmacy australia: online pharmacy china – mexican pharmacy online

Iver Therapeutics Iver Therapeutics generic ivermectin

https://smartgenrxusa.com/# canadian pharmacy levitra

sertraline zoloft: zoloft medication – zoloft medication

Sertraline USA: zoloft buy – sertraline generic

http://neuroreliefusa.com/# Neuro Relief USA

Smart GenRx USA Smart GenRx USA Smart GenRx USA

Smart GenRx USA: world pharmacy india – canadian pharmacy levitra value pack

http://ivertherapeutics.com/# Iver Therapeutics

Sertraline USA: sertraline zoloft – zoloft without dr prescription

http://neuroreliefusa.com/# buy neurontin online

Iver Therapeutics: Iver Therapeutics – Iver Therapeutics

online pharmacy delivery usa Smart GenRx USA online pharmacy without insurance

http://smartgenrxusa.com/# Smart GenRx USA

Neuro Relief USA: Neuro Relief USA – neurontin uk

http://ivertherapeutics.com/# Iver Therapeutics

Neuro Relief USA: neurontin 1800 mg – Neuro Relief USA

http://ivertherapeutics.com/# stromectol order online

stromectol medicine purchase ivermectin ivermectin 3 mg

Iver Therapeutics: ivermectin 3mg – stromectol online pharmacy

https://sertralineusa.com/# order zoloft

neurontin 30 mg: Neuro Relief USA – Neuro Relief USA

https://smartgenrxusa.shop/# Smart GenRx USA

order zoloft zoloft tablet zoloft without rx

buy zoloft: sertraline – buy zoloft

http://neuroreliefusa.com/# neurontin from canada

order zoloft: zoloft medication – zoloft medication

https://sertralineusa.shop/# zoloft cheap

zoloft generic: sertraline – sertraline

gabapentin 600 mg neurontin prescription medication neurontin prescription medication

https://ivertherapeutics.com/# stromectol 6 mg tablet

stromectol xr: Iver Therapeutics – stromectol price us

https://ivertherapeutics.com/# buy stromectol online uk

canadian pharmacy generic cialis: legitimate canadian pharmacies – online pharmacy uk

http://ivertherapeutics.com/# ivermectin price canada

Iver Therapeutics: Iver Therapeutics – stromectol without prescription

gabapentin online neurontin medication order neurontin over the counter

http://sertralineusa.com/# zoloft pill

zoloft medication: zoloft medication – zoloft cheap

pharmacy websites: Smart GenRx USA – Smart GenRx USA

http://smartgenrxusa.com/# canadian pharmacy no scripts

prescription free canadian pharmacy Smart GenRx USA Smart GenRx USA

ivermectin 1 cream 45gm: Iver Therapeutics – stromectol price us

sertraline generic: order zoloft – order zoloft

zoloft cheap: sertraline – zoloft cheap

https://sertralineusa.shop/# zoloft medication

viagra from canadian pharmacy online pharmacy prescription п»їcanadian pharmacy online

neurontin 300mg tablet cost: neurontin 400 – Neuro Relief USA

us pharmacy: Smart GenRx USA – low cost online pharmacy

https://ivertherapeutics.com/# Iver Therapeutics

zoloft pill: zoloft buy – zoloft without dr prescription

https://smartgenrxusa.shop/# the pharmacy

http://smartgenrxusa.com/# online pharmacy price checker

Neuro Relief USA can you buy neurontin over the counter Neuro Relief USA

cost of ivermectin cream: Iver Therapeutics – Iver Therapeutics

https://smartgenrxusa.shop/# canadian discount pharmacy

buy stromectol pills: Iver Therapeutics – ivermectin pills

http://smartgenrxusa.com/# professional pharmacy

Smart GenRx USA: canada pharmacy reviews – Smart GenRx USA

https://neuroreliefusa.com/# neurontin 400 mg

http://neuroreliefusa.com/# Neuro Relief USA

Iver Therapeutics ivermectin 4 ivermectin generic

order zoloft: zoloft pill – generic zoloft

http://neuroreliefusa.com/# Neuro Relief USA

Iver Therapeutics: Iver Therapeutics – Iver Therapeutics

https://ivertherapeutics.shop/# generic ivermectin

Iver Therapeutics: ivermectin 1 topical cream – stromectol pills

https://ivertherapeutics.com/# Iver Therapeutics

http://neuroreliefusa.com/# neurontin 100mg price

zoloft pill generic for zoloft zoloft pill

Iver Therapeutics: Iver Therapeutics – Iver Therapeutics

Iver Therapeutics: stromectol pills – Iver Therapeutics

https://ivertherapeutics.shop/# Iver Therapeutics

canadian pharmacy online cialis: Smart GenRx USA – onlinecanadianpharmacy 24

http://neuroreliefusa.com/# brand name neurontin

https://neuroreliefusa.shop/# purchase neurontin online

Iver Therapeutics: stromectol pills – ivermectin drug

ivermectin 1 cream: Iver Therapeutics – Iver Therapeutics

http://sertralineusa.com/# sertraline zoloft

Neuro Relief USA Neuro Relief USA neurontin 900

where to buy stromectol online: Iver Therapeutics – stromectol medicine

https://sertralineusa.shop/# buy zoloft

Smart GenRx USA: Smart GenRx USA – Smart GenRx USA

https://smartgenrxusa.com/# Smart GenRx USA

buy zoloft: Sertraline USA – zoloft without dr prescription

generic zoloft: buy zoloft – zoloft generic

https://neuroreliefusa.shop/# neurontin 10 mg

Iver Therapeutics Iver Therapeutics Iver Therapeutics

buy ivermectin canada: stromectol covid 19 – ivermectin 1 topical cream

http://ivertherapeutics.com/# stromectol uk buy

Iver Therapeutics: stromectol covid 19 – Iver Therapeutics

neurontin price australia: neurontin capsule 600mg – medicine neurontin capsules

Neuro Relief USA: neurontin brand name – neurontin tablets

https://sertralineusa.shop/# order zoloft

zoloft generic order zoloft zoloft without dr prescription

zoloft without rx: zoloft medication – zoloft buy

https://ivertherapeutics.com/# Iver Therapeutics

Smart GenRx USA: global pharmacy canada – Smart GenRx USA

cost of stromectol medication: stromectol nz – Iver Therapeutics

https://sertralineusa.com/# generic for zoloft

neurontin 400 mg capsules: Neuro Relief USA – Neuro Relief USA

https://sertralineusa.com/# zoloft buy

zoloft medication: zoloft generic – Sertraline USA

Smart GenRx USA: viagra online canadian pharmacy – canadian online pharmacy cialis

https://smartgenrxusa.shop/# online pharmacy no presc uk

https://neuroreliefusa.shop/# Neuro Relief USA

Smart GenRx USA: Smart GenRx USA – rate canadian pharmacies

stromectol medicine: ivermectin 10 mg – ivermectin 3 mg tabs

https://neuroreliefusa.shop/# Neuro Relief USA

Smart GenRx USA Smart GenRx USA Smart GenRx USA

stromectol cream: buy stromectol uk – Iver Therapeutics

https://ivertherapeutics.com/# ivermectin humans

stromectol oral: ivermectin humans – Iver Therapeutics

https://smartgenrxusa.com/# Smart GenRx USA

usa pharmacy: Smart GenRx USA – Smart GenRx USA

https://smartgenrxusa.com/# Smart GenRx USA

canada neurontin 100mg lowest price: Neuro Relief USA – neurontin 100mg tablets

https://smartgenrxusa.com/# Smart GenRx USA

buy neurontin uk: Neuro Relief USA – neurontin brand coupon

zoloft buy sertraline generic sertraline generic

https://neuroreliefusa.com/# Neuro Relief USA

Smart GenRx USA: Smart GenRx USA – mexican pharmacy

where to buy ivermectin: Iver Therapeutics – Iver Therapeutics

http://neuroreliefusa.com/# Neuro Relief USA

https://sertralineusa.com/# zoloft without dr prescription

sertraline generic: sertraline – zoloft without rx

https://ivertherapeutics.shop/# Iver Therapeutics

Smart GenRx USA: Smart GenRx USA – Smart GenRx USA

Iver Therapeutics: Iver Therapeutics – ivermectin online

neurontin 800 mg tablets best price neurontin 800 mg tablet neurontin 150 mg

http://smartgenrxusa.com/# Smart GenRx USA

Iver Therapeutics: ivermectin price canada – buy stromectol

Neuro Relief USA: neurontin capsules 300mg – neurontin from canada

http://neuroreliefusa.com/# Neuro Relief USA

https://smartgenrxusa.com/# pharmacy rx

buy generic neurontin: Neuro Relief USA – neurontin prescription

Neuro Relief USA: Neuro Relief USA – Neuro Relief USA

https://neuroreliefusa.shop/# Neuro Relief USA

Smart GenRx USA canadian pharmacy review best online pharmacy

Neuro Relief USA: Neuro Relief USA – drug neurontin

https://ivertherapeutics.shop/# stromectol generic name

http://ivertherapeutics.com/# stromectol ivermectin buy

Smart GenRx USA: express scripts pharmacy – gold pharmacy online

Neuro Relief USA: Neuro Relief USA – neurontin 600 mg

https://smartgenrxusa.shop/# med pharmacy

Smart GenRx USA: best value pharmacy – legit canadian pharmacy

zoloft no prescription: sertraline generic – zoloft buy

http://ivertherapeutics.com/# Iver Therapeutics

Neuro Relief USA neurontin generic buy neurontin online uk

http://sertralineusa.com/# zoloft tablet

https://neuroreliefusa.shop/# medicine neurontin capsules

buy neurontin uk: cheap neurontin – neurontin price south africa

Neuro Relief USA: Neuro Relief USA – Neuro Relief USA

http://ivertherapeutics.com/# Iver Therapeutics

buy cheap neurontin: Neuro Relief USA – order neurontin

ivermectin 9 mg: ivermectin where to buy for humans – Iver Therapeutics

https://neuroreliefusa.shop/# neurontin gabapentin

https://neuroreliefusa.shop/# Neuro Relief USA

no prescription pharmacy paypal certified canadian pharmacy legal online pharmacy coupon code

sertraline: order zoloft – zoloft tablet

purchase neurontin: Neuro Relief USA – neurontin 10 mg

Neuro Relief USA: where to buy neurontin – where can i buy neurontin from canada

https://smartgenrxusa.shop/# Smart GenRx USA

https://sertralineusa.shop/# generic for zoloft

neurontin brand name: Neuro Relief USA – Neuro Relief USA

zoloft pill: generic zoloft – zoloft cheap

where can i buy neurontin online Neuro Relief USA Neuro Relief USA

generic zoloft: order zoloft – zoloft without dr prescription

zoloft generic: zoloft without dr prescription – zoloft without dr prescription

https://sertralineusa.shop/# zoloft without dr prescription

Iver Therapeutics: Iver Therapeutics – Iver Therapeutics

https://sertralineusa.shop/# zoloft tablet

zoloft medication: zoloft cheap – order zoloft

Neuro Relief USA: Neuro Relief USA – neurontin 400 mg tablets

sertraline zoloft sertraline generic zoloft medication

http://ivertherapeutics.com/# Iver Therapeutics

reputable indian online pharmacy: canadian pharmacy uk delivery – Smart GenRx USA

Neuro Relief USA: Neuro Relief USA – neurontin 300 mg

https://smartgenrxusa.com/# online pharmacy without prescription

https://neuroreliefusa.shop/# cost of brand name neurontin

Neuro Relief USA: neurontin 900 – Neuro Relief USA

Neuro Relief USA: Neuro Relief USA – Neuro Relief USA

medical pharmacy online pharmacy quick delivery Smart GenRx USA

ivermectin nz: Iver Therapeutics – buy ivermectin canada

http://neuroreliefusa.com/# Neuro Relief USA

https://ivertherapeutics.com/# Iver Therapeutics

zoloft buy: zoloft generic – sertraline

neurontin for sale: neurontin prices – neurontin gabapentin

https://ivertherapeutics.shop/# Iver Therapeutics

pharmacy com: cheapest pharmacy – Smart GenRx USA

cost of ivermectin 1% cream: Iver Therapeutics – ivermectin human

http://smartgenrxusa.com/# canadian pharmacy sildenafil

zoloft medication generic zoloft generic zoloft

https://ivertherapeutics.shop/# Iver Therapeutics

buy zoloft: zoloft no prescription – zoloft pill

ivermectin cream 5%: ivermectin 50 mg – Iver Therapeutics

http://neuroreliefusa.com/# Neuro Relief USA

https://sertralineusa.shop/# buy zoloft

zoloft pill: zoloft without dr prescription – zoloft without dr prescription

Smart GenRx USA: legal online pharmacy coupon code – Smart GenRx USA

https://neuroreliefusa.shop/# Neuro Relief USA

zoloft medication: sertraline generic – zoloft without dr prescription

pharmacy Smart GenRx USA Smart GenRx USA

https://sertralineusa.com/# zoloft without dr prescription

vet pharmacy online: VetFree Meds – vet pharmacy online

https://vetfreemeds.shop/# discount pet meds

mexico pharmacy price list: mexico drug store – My Mexican Pharmacy

https://mymexicanpharmacy.shop/# My Mexican Pharmacy

http://vetfreemeds.com/# pet meds official website

canadian pharmacy meds: CertiCanPharmacy – vipps approved canadian online pharmacy

pet meds for dogs VetFree Meds online vet pharmacy

My Mexican Pharmacy: pharmacies in mexico that ship to the us – My Mexican Pharmacy

https://certicanpharmacy.com/# CertiCanPharmacy

I love looking through an article that can make men and women think. Also, thanks for allowing for me to comment. Life Experience Degree

http://mymexicanpharmacy.com/# My Mexican Pharmacy

My Mexican Pharmacy: order medication from mexico – My Mexican Pharmacy

http://vetfreemeds.com/# pet meds for dogs

My Mexican Pharmacy: order medication from mexico – farmacia pharmacy mexico

https://certicanpharmacy.shop/# CertiCanPharmacy

pet drugs online: VetFree Meds – canada pet meds

dog prescriptions online dog prescriptions online discount pet meds

http://mymexicanpharmacy.com/# mexican online pharmacy

best pet rx: VetFree Meds – discount pet meds

https://mymexicanpharmacy.shop/# My Mexican Pharmacy

http://vetfreemeds.com/# vet pharmacy

My Mexican Pharmacy: best mexican online pharmacy – My Mexican Pharmacy

online pet pharmacy: VetFree Meds – pet drugs online

http://vetfreemeds.com/# pet pharmacy

canadian pharmacy drugs online online pharmacy canada northern pharmacy canada

CertiCanPharmacy: online canadian pharmacy – canadapharmacyonline legit

https://mymexicanpharmacy.shop/# My Mexican Pharmacy

http://certicanpharmacy.com/# canada rx pharmacy

best canadian pharmacy online: CertiCanPharmacy – the canadian pharmacy

pet prescriptions online: discount pet meds – pet pharmacy online

https://certicanpharmacy.com/# canadianpharmacy com

Explicit content sites offer a variety of videos for adult entertainment.

Opt for reliable platforms for a safe experience.

Here is my web-site … buy cannabis online

best pet rx: VetFree Meds – vet pharmacy

п»їdog medication online VetFree Meds online vet pharmacy

http://mymexicanpharmacy.com/# My Mexican Pharmacy

https://vetfreemeds.com/# vet pharmacy online

CertiCanPharmacy: adderall canadian pharmacy – CertiCanPharmacy

mexican pharmacies that ship: My Mexican Pharmacy – My Mexican Pharmacy

https://mymexicanpharmacy.shop/# mail order pharmacy mexico

https://certicanpharmacy.shop/# canadian pharmacy ltd

safe online pharmacies in canada: CertiCanPharmacy – escrow pharmacy canada

canadian pharmacy reviews: certified canadian international pharmacy – CertiCanPharmacy

http://certicanpharmacy.com/# CertiCanPharmacy

mexico pet pharmacy online mexico pharmacy My Mexican Pharmacy

My Mexican Pharmacy: online pharmacy mexico – My Mexican Pharmacy

https://vetfreemeds.shop/# online pet pharmacy

http://vetfreemeds.com/# dog prescriptions online

canadian pharmacy 24 com: CertiCanPharmacy – CertiCanPharmacy

pharmacy mexico: mexico pharmacy – My Mexican Pharmacy

http://vetfreemeds.com/# pet med

https://vetfreemeds.com/# pet meds online

canadianpharmacymeds com: canada pharmacy online legit – CertiCanPharmacy

legit canadian pharmacy CertiCanPharmacy CertiCanPharmacy